The Shocking Reality of Iron Capsules Manufacturing in Karnataka What Consumers Should Know

Table of Contents

Iron supplements play a crucial role in addressing common health issues like anemia and iron deficiencies, which affect millions of people worldwide. As a vital mineral for the body, iron is necessary for producing hemoglobin, supporting the immune system, and ensuring overall well-being. With the growing demand, Iron Capsules Manufacturing in Karnataka has become an essential part of the healthcare industry, providing a vital solution to these widespread health concerns.

Iron pill demand has increased recently, especially in Karnataka and throughout India, as a result of growing health consciousness and knowledge of dietary deficiencies. Every user should be informed of some unexpected and little-known facts regarding the production methods used to make these capsules, nevertheless, given the spike in demand.

This blog aims to uncover some of these hidden realities related to the production, quality control, and regulatory standards governing iron capsules.

The Demand for Iron Capsules in Karnataka

About 50% of women and 25% of men in Karnataka suffer from iron deficiency and anaemia, which are common problems in the state. Given that iron shortage can result in major health issues, the situation is especially problematic for youngsters and expectant mothers. The region's need for iron supplements has grown dramatically as a result of these figures.

Pharmaceutical manufacturers are creating and distributing iron capsules, which is a critical step in meeting this healthcare requirement. These businesses are making sure that the public has access to safe and efficient iron supplements in an effort to address the growing need for anaemia awareness.

Quality Standards in Manufacturing

High-quality raw materials, such as iron salts, are carefully processed and combined with excipients to create iron capsules. To guarantee safety, the combination is subsequently sealed and packed according to stringent hygienic guidelines.

Manufacturers must follow Good Manufacturing Practices (GMP), which ensure the production of safe, effective products. GMP guidelines cover everything from raw material quality to equipment cleanliness and final product inspection, ensuring consistency and safety.

Despite these standards, some local manufacturers face challenges with quality control. Issues like inconsistent raw material sourcing, inadequate testing, and lapses in adherence to GMP can lead to variations in product quality, making it crucial for consumers to choose trusted brands.

Common Issues in Iron Capsule Manufacturing

1. Substandard or Contaminated Raw Materials: Some manufacturers may use lower-quality or contaminated iron salts, compromising the effectiveness and safety of the capsules.

2. Inaccurate Dosage: Inadequate dosage precision can result in capsules with either too little iron, leading to insufficient efficacy, or too much, causing potential side effects.

3. Poor Storage and Handling: Improper storage conditions, such as exposure to moisture or temperature extremes, can degrade the quality of iron capsules and reduce their potency.

4. Counterfeit Capsules: The circulation of counterfeit iron capsules in the market poses a significant risk, as these products may contain harmful ingredients or incorrect dosages, threatening consumer health.

Regulatory Oversight in Karnataka

State and central regulatory authorities, like the Drugs Control Department and CDSCO, ensure iron capsule safety through strict manufacturing and quality control guidelines. They conduct inspections to ensure compliance with regulations.

Despite this, enforcement can be inconsistent, particularly among smaller manufacturers, leading to potential quality lapses. Third-party audits and certifications play a key role in ensuring products meet safety and quality standards.

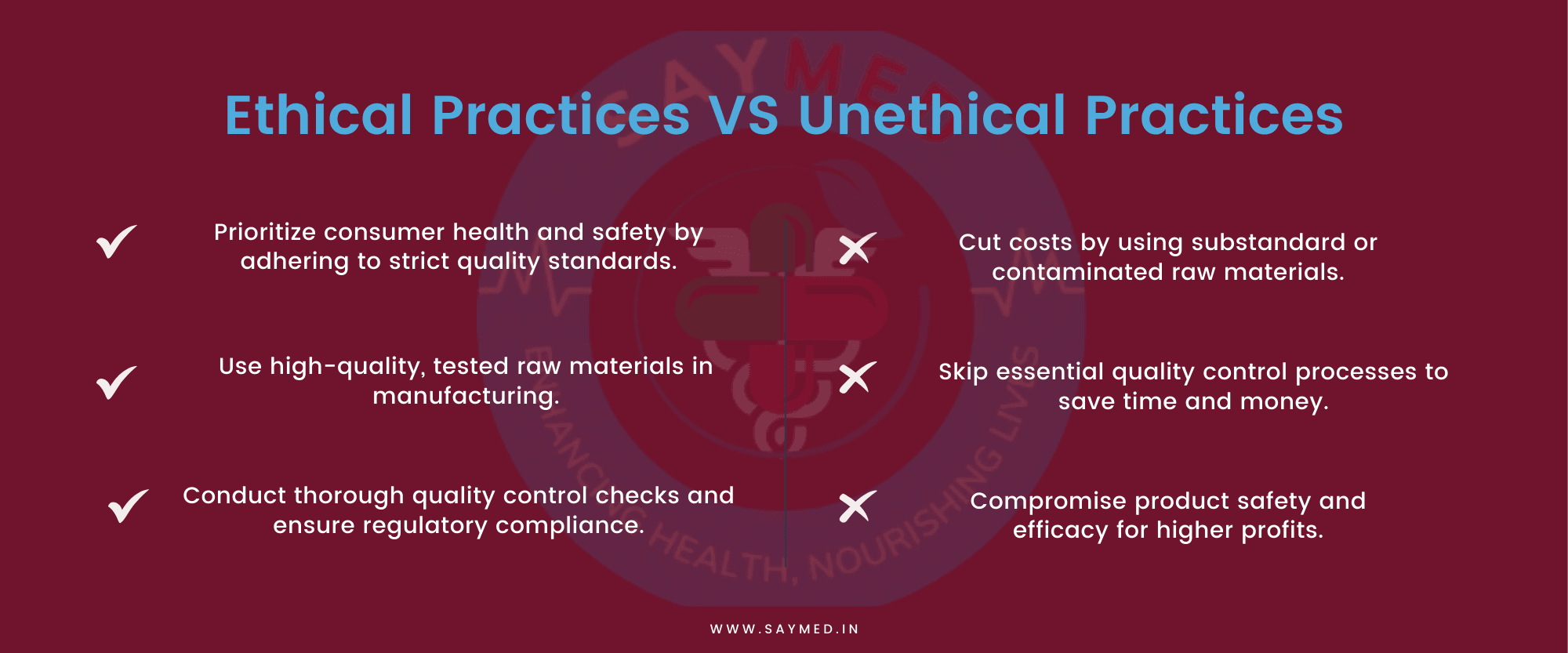

Ethical vs. Unethical Practices in the Industry

Commitment to Excellence in Iron Supplement Production

In the competitive world of iron supplement manufacturing, companies like Saymed understand the importance of quality. Through a combination of stringent production protocols, high-quality raw materials, and advanced testing methods, Saymed is dedicated to providing iron capsules that meet both consumer needs and safety standards. Every step of the process, from sourcing to final testing, is handled with a focus on excellence, ensuring that the end product is both effective and reliable.

Conclusion

In conclusion, the growing demand for iron supplements in Karnataka has brought attention to the complexities of iron capsules manufacturing in Karnataka. While there are ethical companies committed to high-quality production, consumers must remain cautious of potential quality lapses and unethical practices. By choosing trusted brands like Saymed, consumers can ensure they receive safe and effective iron capsules.